The chair is named after my mother: Teresa.

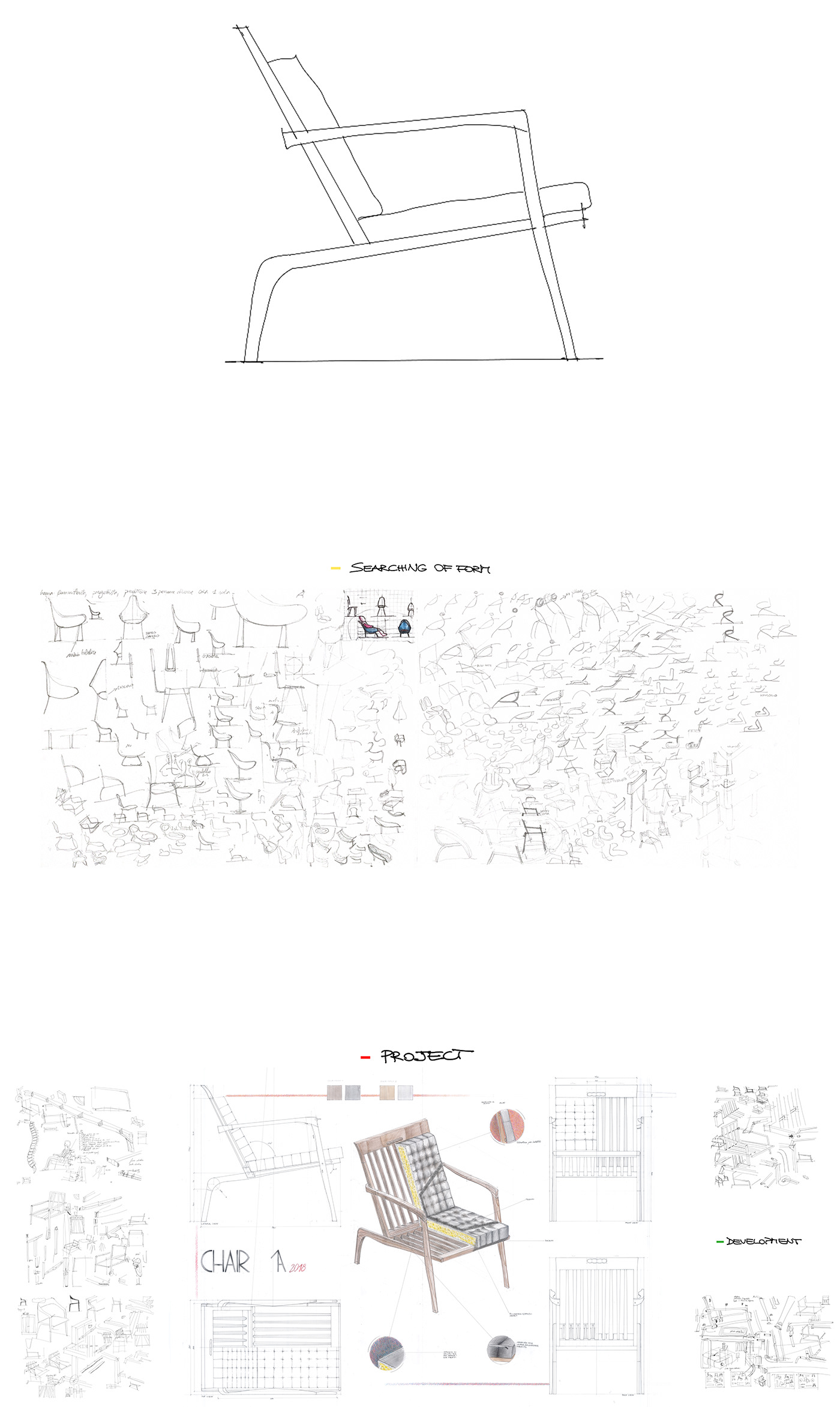

I developed this chair as I attended my 4th year of High School after having completed a long research through the most iconic chairs from the Industrial Revolution to modern days. After that I was asked to come up with an idea that could sum up what I had learned as well as what shape I wanted to give to my first chair ever. We pretended to have a real client (my professor) and to have actual guidelines, which we had not. Anyway, after several attempts in order to reach the perfect balance of what I wanted and what my client asked the final outcome is as follow.

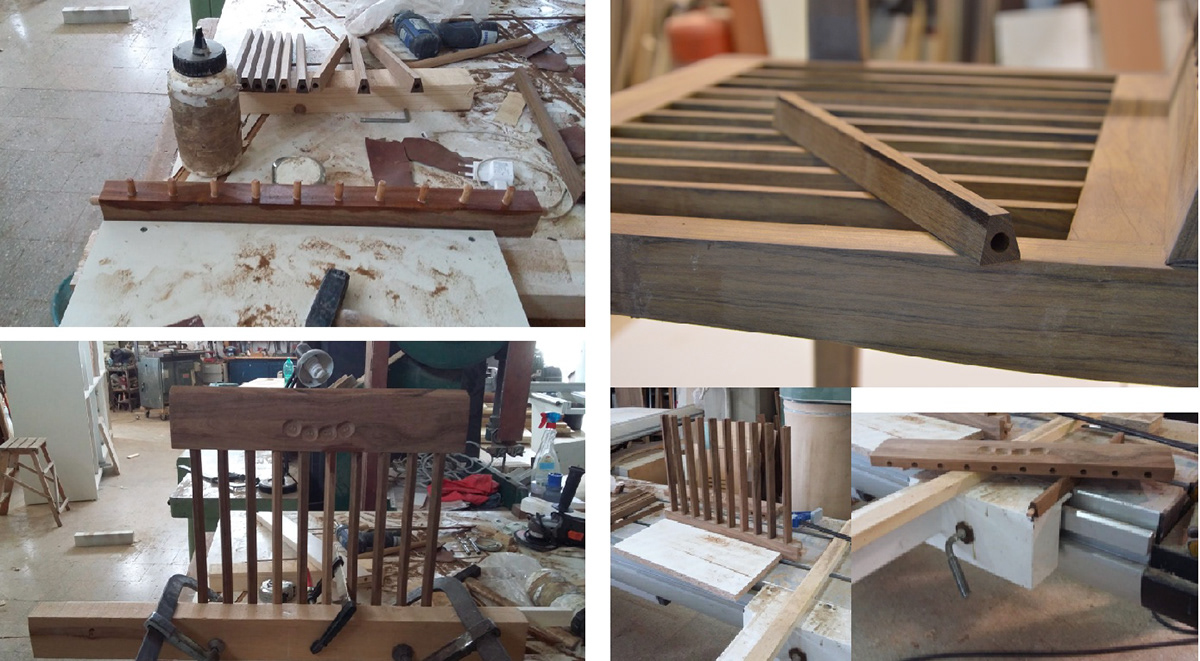

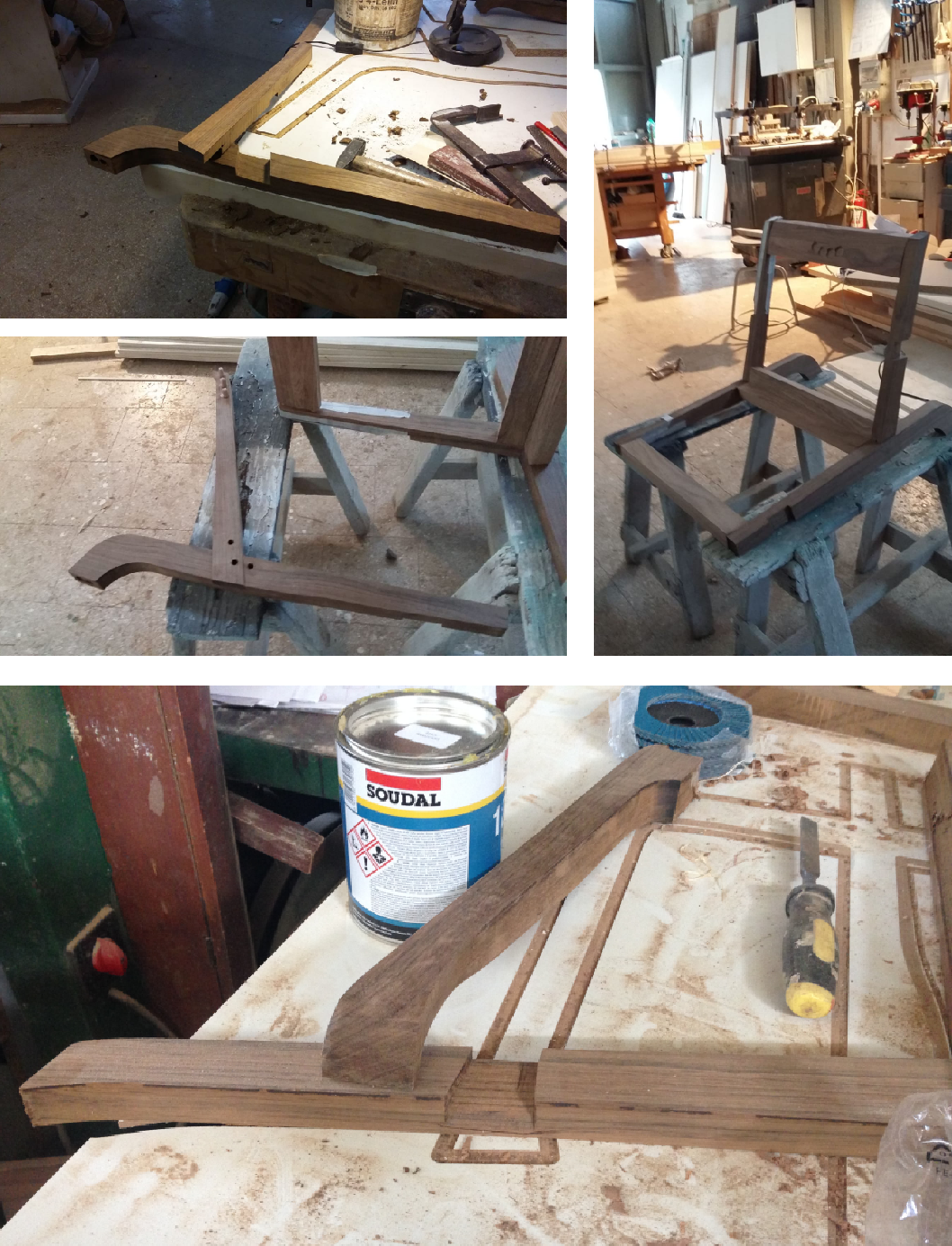

The manufacturing process was quite off-putting. Being my first chair and, let's say, the first serious object in terms of money invested and time spent to figure out how I could create a shape meaningful without putting the ergonomic in the background it's been a hell of a journey looking for the right carpenter for this job. I finally got it through in August when the work began.

The Profile: we changed measures several times due to my lack of experience. As you can see there are some pencil strokes that highlight the new radious.

The CNC machine: in this phase we were working on the pieces that we were going to assemble to the legs.

Gluing the arms to the main leg. The piece below was definitely one of the most compelling, I had absolutely no idea how such difficult chairs (the ones you'd probably see in design shows) were shaped. It's all elbow grease and hand polishing, aside the use of clamps.

The handle, even though it's meant to be carved out all the way up in order to have a better grasp so that the chair could be moved with ease. We eventually opted to reduce the wast of material and CNC work.

Look at the amazing "cut–off triangle shape'' that will serve as supports and base for the upholstered ahed. Design is in the details despite slight differences from the main project.

The chair is getting all shaped up. Here, upper part and lower part assembled together. We had to create the negative forms for the back and the arms, this simple trick allowed us to better arrange the chunks.

Digging and cutting the specular side supports. The project along with the changes always handy.

Teresa substantially ready to be sit on, just some finishes to add the cherry on the cake.

This cylinder–shaped like chunk with an unobtrusive ornament in the middle came out of nowhere. Do you want to know what is that? It's the answer to all of those who think that a chair doesn't require set of rules, mechanical gimmick or rods. It is not in the project because I didn't know I would have needed one. Ah, and for the record the tool in the first picture is a lathe.

Unfortunately the artisan didn’t have the culture of “taking the photos on the go”. I whish I could have taken more to give you more hint on how the padded pillow was made.

Choosing the material was a new experience to me, and at first impact quite overwhelming. Right column third from below.

The artisan in order to give the pillow the perfect slope has needed the reverse profile of the chair itself which I accurately drew on cardboard.

And here we are. Perfect combo: pillow, reference cardboard, samples and lab in which all was created.

Chair.

Teresa Chair featured on:

Chair on Sale on Faberin looking for a manufacturer.

More Design Contents on Instagram.